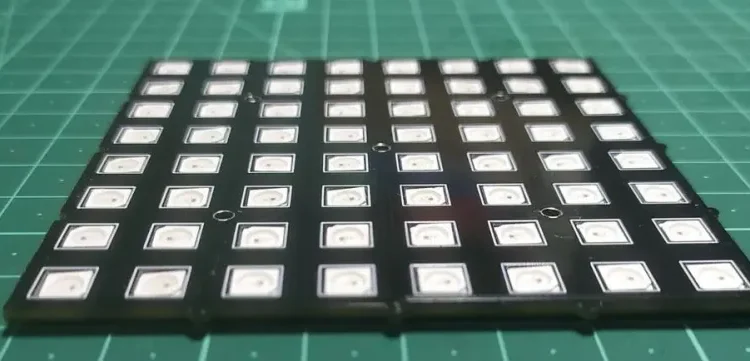

LED PCB refers to led printed circuit board used in LED lighting; Common types include aluminum-based PCB, FR4 PCB, CEM1 and CEM3 PCB. With the popularity of LED lighting, the demand for led pcb board is increasing too. Many European and American customers began to set up SMD factories or LED lighting assembly factories in the local area, importing led circuit board from China, and then assembling them into lightings for sale. JHDPCB has been producing LED PCBs since 2009, and our production scale has reached the top 5 in China. Our led pcbs are exported to more than 100 countries.

What Are the Types of LED PCB?

Aluminum PCB / MC PCB:

Aluminum pcb or mc pcb is the most widely used in LED lighting industry because of its excellent thermal conductivity. For high-power LED lighting, in order to prolong the service life of led chips or components, it is recommended to use aluminum substrate pcb. Especially the metal core pcb with high thermal conductivity. For example, aluminum pcb 1.5W/m.k, aluminum pcb 2.0W/m.k and aluminum pcb 3.0W/m.k, up to 10W/m.k or copper pcb.

Fr4 PCB:

Fr4 PCB is also used in LED lighting much, because FR-4 PCB has many advantages, such as light weight, good insulation performance, good dimensional stability, easy processing shape, etc. FR4 PCB can be considered for some low-power lighting or lighting with high insulation requirements. Click to view detailed FR4 material properties and related knowledge in PCB manufacturing.

Cem1 PCB:

Cem1 PCB is a semi-glass fiber material, which is often used as a substitute for FR4 PCB in the LED lamp industry. The difference is that cem1 is not resistant to high temperatures and is not suitable for reflow soldering above 240 ℃.

Cem3 PCB:

The same as cem1 PCB, cem3 PCB is made of semi-glass fiber, their material quality and functional characteristics are basically the same. The two can be used interchangeably. However, the material is usually not changed for PCB repeat order, which is conducive to maintaining the stability of PCB quality.

Flexible led PCB:

The flexible pcb is also commonly used for LED lighting. The flexible PCB for led has excellent bending resistance and can make different bends and radians with lamps or led strips.

What Is Through-Hole Assembly(THA)?

Through-hole technology has a lasting effect with its reliability and strength, and still win a large market advantage. THA-Through hole assembly is difficult to meet the demands of modern electronic products. Nowadays, SMT technology has almost replaced the through-hole design in PCB manufacturing. But through-hole assembly still impossible to replace in some applications, such as large transformers, electrolytic capacitors, connectors, etc.

What Is A Through-Hole Component(THC)?

THC-Through-hole components (also known as “through-hole”) are a mounting solution for electronic circuits in which components are fixed by wire. A mounting process in which wires are plugged into holes on a printed circuit board (PCB) and components are soldered to the PCB board by wave soldering or hand soldering.

JHD Capability Of Through Hole Assembly Services.

We are fully capable of handling the following china through hole pcb assembly services:

Dual Wave Flow Solder;

Automatic and manual component placement;

RoHS automated through hole soldering using tin-lead solder;

functional testing;

Choose JHDPCB as Your PCB Supplier or Partner.

At JHDPCB, our LED industry expertise and services will help you get the best PCB solution. Contact us for led pcb price or questions about our process capabilities.