There is a lot of confusion surrounding surface roughness and what it means for manufacturing. In this blog post, we will break down surface roughness and explain what it is and how it affects your products. We will also discuss the different types of surface roughness and how to measure them. By the end of this post, you will have a better understanding of surface roughness and how to use it to improve your products!

What is surface roughness?

Surface roughness is a measure of the irregularities on the surface of a material. These irregularities can be caused by many factors, including manufacturing processes, wear and tear, and environmental conditions. Surface roughness can have a major impact on the performance of a product, as it can affect everything from friction to heat transfer.

There are two main types of surface roughness: micro roughness and macro roughness. Micro roughness is the surface irregularities that are too small to be seen with the naked eye. Macro roughness, on the other hand, is the surface irregularities that can be seen with the naked eye.

How is surface roughness measured?

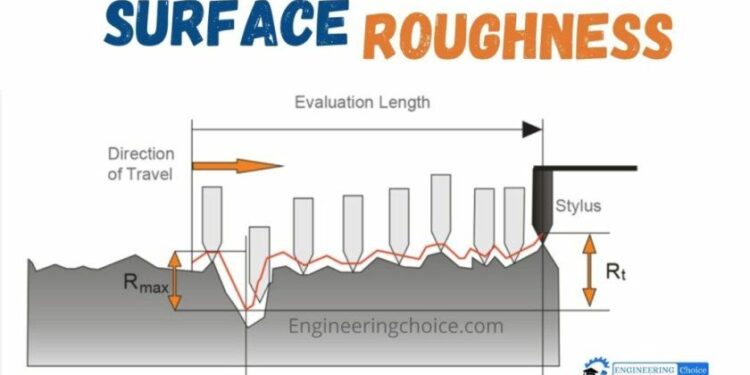

There are a few different ways to measure surface roughness. The most common method is to use a surface profilometer. This instrument uses a stylus to measure the surface irregularities. Another common method is to use a white light interferometer. This instrument uses interference patterns to measure surface roughness.

The grade of surface roughness

It is typically expressed in micrometers (µm). The lower the grade, the smoother the surface. For example, a surface with a grade of 0.05 µm is much smoother than a surface with a grade of 0.50 µm.

What are the different types of surface roughness?

There are three main types of surface roughness: waviness, lay, and texture.

Waviness is the irregularities that occur in a regular pattern. These irregularities can be caused by factors such as vibration or machining processes.

Lay is the direction of the surface irregularities. Lay can be caused by the way a material is processed or how it is used.

Texture is the surface irregularities that are not in a regular pattern. Texture can be caused by many factors, including the type of material and the manufacturing process.

How does surface roughness affect products?

Surface roughness has a major impact on the performance of products. It can affect everything from friction to heat transfer. surface roughness can also affect the aesthetics of a product.

What are the benefits of surface roughness?

Surface roughness can have many benefits, depending on the application. In some cases, surface roughness can improve the performance of a product by increasing surface area or enhancing heat transfer. In other cases, surface roughness can be used to improve the aesthetics of a product.

What are the drawbacks of surface roughness?

Surface roughness can also have some drawbacks. In some cases, surface roughness can cause friction and wear on components. In other cases, surface roughness can trap dirt and debris, which can lead to corrosion.

How can surface roughness be controlled?

There are a few different ways to control surface roughness. The most common method is to use surface finishing processes, such as grinding or polishing. These processes can remove irregularities and create a smooth surface. In some cases, surface roughness can also be controlled by changing the manufacturing process or using different materials.

Surface roughness is an important factor to consider in manufacturing. By understanding surface roughness and how it affects your products, you can improve the performance and aesthetics of your products. By controlling surface roughness, you can also reduce friction and wear on components. Use surface finishing processes to create a smooth surface and control surface roughness in your products!