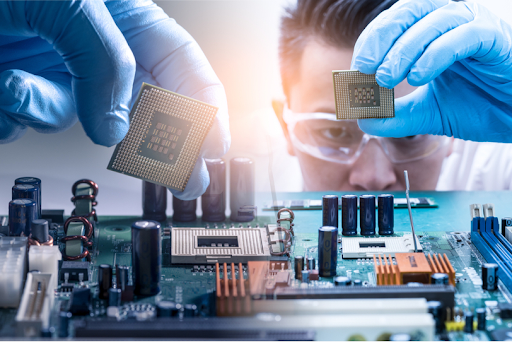

The most common technology used to create integrated circuits is CMOS technology. Also known as Complementary Metal Oxide Semiconductor. This technology is used in microprocessors, batteries, and digital sensors, among other electronic components, for a number of reasons. Hence, CMOS-based electronics driver testing has become essential for introducing high-tech devices.

Before comprehending the significance of CMOS technology. Let’s understand how testing benefits the tech industries and why it’s significant to do.

Advantages of Testing

A test apparatus is utilized to generate signals and record the corresponding responses from electrical and electronic DUTs (Devices Under Test). This makes it simple to demonstrate the DUT’s correct functionality and, in addition, to identify any device flaws. Below you will discover some general benefits of pin electronics testing:

➤Greater consistency

Despite their best efforts, people frequently perform the same task in slightly different ways. When a testing tool is used, it will precisely replicate its previous actions, ensuring that the outcome remains constant.

➤Less Load on Engineers

Testing is less dependent on the availability of the test engineers, thanks to ATE pin electronics. Plus, the automated tests may be executed constantly in a round-the-clock setting as they offer comprehensive coverage.

➤Increase Test Engineers’ Knowledge & Use Fewer Resources

In comparison to manual testing, automated testing uses significantly fewer resources during execution. Additionally, it assists in educating test engineers and expanding their knowledge.

➤More Productivity

It serves as a test data generator and generates as much test data as possible to cover a wide range of input and anticipated output for result comparison.

➤ Fewer Errors and Availability of Time

Automated testing is more reliable since there are fewer opportunities for error. In addition, test engineers have free time, much like automated testing, and can concentrate on other creative projects.

Why Electronics Driver Test Instruments are Needed

Due to fair wear out and component material deterioration from exposure to heat, vibration, shock, and other external conditions, the performance of all electrical or electronic equipment tends to deteriorate with time.

The likelihood of equipment failure and electric shock thus rises over time. Therefore, it is generally recommended that frequent calibration and testing be done on all electrical and electronic equipment.

When discussing the measuring processes used in electronics, it is impossible to ignore the measurement significance of voltage, resistance, current, capacitance, inductance, etc.

All the electrical quantities described above cannot be ignored if the testing or fault detection of a circuit is necessary. To ascertain the defect of all components of a circuit, we must take into account all electrical quantities and verify their accuracy. Therefore, tech industries will launch successful products in the market that are safe to use.

Why is CMOS Gaining Popularity?

Prior to CMOS, logic gates were frequently implemented using PMOS and NMOS logic. Then, NMOS Technology, which had previously been the norm for IC manufacture, took the place of PMOS.

At first, CMOS was more expensive and slower than NMOS. The key benefits of NMOS technology are its functional density, speed of processing, and ease of manufacturing. Electrical asymmetry and static power dissipation are the key drawbacks of NMOS technology.

The use of CMOS technology lessens these limitations. The key benefit of CMOS is its low power dissipation, which only happens when a circuit is switched. As more CMOS gates can be integrated into an IC, performance is greatly improved.

Bottom Line

More often, CMOS technology is chosen to create next-generation high-density products. That’s why electronic drivers are developed on CMOS technology to provide accurate testing. Moreover, in today’s era, the competitive market has taken birth. That’s why every tech brand wants to ensure that their device works as per standards. Hence, chip testing is given adequate attention before introducing the electronic item in the market.