A spiral gasket is a mechanical seal that prevents leaking between two surfaces. When shopping for gaskets, you will be presented with a range of options, including metallic, semi-metallic, and nonmetallic. Among those alternatives, we’ll go through spiral-wrapped Flexitallic gaskets in detail in today’s post. This is the most common type of gasket used for high-pressure applications.

Reasons to Choose Flexitallic Gaskets

- Spiral wound gaskets are used for sealing, padding, leak prevention, protection from environmental impurities, mounting, and vibration reduction. In short, it is a multipurpose gasket compatible with various industrial applications.

- They can endure higher pressures, temperatures, and corrosive environments than solid gaskets, and they require less clamping force.

- Because of their chevron-shaped construction, these gaskets provide spring-like padding, making them suited for a variety of work environments.

- Because of their dependability and toughness, these gaskets also prevent gear failure and the accompanying costs.

- Flexitallic gaskets can be designed to fit a broad range of working conditions by combining different winding components and metals, and they’re also relatively simple to install.

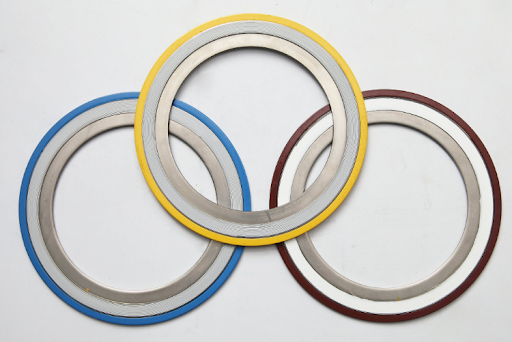

- An outer ring on spiral wound gaskets makes installation easier and prevents the gaskets from blowing out.

- The inner gasket ring reduces turbulence and reduces flow resistance by inhibiting the radial flow of soft fillers.

- When spiral wound gaskets are exposed to high temperatures, the inner ring of the gasket also acts as a heat barrier.

- The spiral wound gasket’s middle ring, like the inner ring, shields the spiral wound component and contributes to the gasket’s safety against blow-out.

- The middle ring also acts as a pressure controller, avoiding over-compression of the spiral wound part.

Important Considerations in Gasket Design

- A bulb large enough to fill the gap is required for metallic gaskets. This is how a long-lasting seal will be created with minimal effort. Isn’t it true that a basic door seal is necessary to fill up all the spaces between the dorr’s edges? When you close the door, the seal is squeezed, preventing dust, dirt, wind, and rain from entering.

- Rubber profiles for gaskets come in a variety of forms. D-seals, P-seals, E-seals, and lip seals are all options. Gather all of the seller’s information and decide which one is best for you. If you’re having trouble deciding, ask the vendor for assistance.

- The durometers of all rubber compounds are available in a variety of sizes. For those unfamiliar with the term, a durometer is a scale that is used to quantify the hardness of a gasket. A suitable durometer can be obtained depending on the gasket application.

These advantages explain why spiral wound gaskets are advantageous in general. However, each ring has its own set of advantages, which is why it’s critical to use both outer and inner rings in gaskets that weigh more than 600 pounds, as this improves the operating reliability of the spiral wound’s sealing feature. Make sure you are buying these gaskets from authorized suppliers only. There are even several third-party online suppliers who offer boiler gaskets of multiple brands without any extra cost.