Choosing the right heavy duty gas struts can make all the difference in safety, durability, and performance. Whether you’re replacing old ones or installing new equipment, getting it right saves time and money. Here’s how to choose the best from Schutts Industrial, your trusted supplier of rugged industrial components.

Key Factors to Consider

1. Load Capacity & Force

First, determine how much force the strut needs to lift or support. Heavy lids, doors, or panels require a higher force. Schutts Industrial offers gas struts in multiple force ratings across ranges like 6/15, 8/18, 10/22, and 14/28. Match the load to the right force specification to avoid struts being underpowered (leading to sag) or overpowered (causing damage).

2. Extended & Compressed Lengths

You’ll need to measure both the fully extended length of the strut and how compact it needs to be when compressed. The workspace available, door open angles, and bracket placement all depend on these dimensions. Heavy duty gas struts from Schutts Industrial include various length choices to suit different setups.

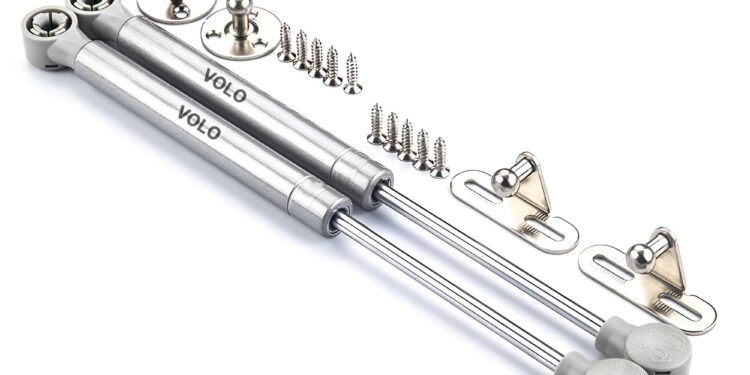

3. Tube & Piston Size

Tube (outer cylinder) and piston (rod) diameters affect strength and lifespan. Thicker materials resist bending and damage. Check dimensions like 6-mm, 8-mm, 10-mm, or more. Schutts Industrial provides several size options so you can balance strength and space constraints.

4. End Fittings & Mounting Brackets

How you connect the gas strut to your equipment matters. There are many end fittings (eyes, ball ends, brackets, foot plates) and mounting brackets. The wrong fitting can cause misalignment, reduce performance, and lead to failure. Schutts Industrial stocks matching fittings and brackets for all their heavy duty gas struts ranges.

5. Material & Finish

Gas struts are exposed to wear, weather, moisture, and possibly corrosive conditions. Stainless steel, plated finishes, or protective coatings extend lifespan. Choose materials and finishes that match your environment (indoors, outdoors, marine, etc.). Schutts Industrial’s product lines detail finish and material choices so you get the best match for durability.

6. Additional Features & Service

- Dampening / Controlled Return: Some gas struts include damped motion or soft-close features to prevent slams.

- Adjustability: Adjustable gas struts let you tune the force needed for different loads.

- Warranty & Support: Buying from a reputable supplier like Schutts Industrial gives you access to service, replacement parts, and customer support.

- Easy Ordering: Tools like a gas strut calculator help ensure you choose correctly. Availability and fast service matter too.

Steps to Choose

- Calculate the weight and center of gravity of what needs lifting.

- Determine the required open and closed lengths by measuring actual setup.

- Select force required to smoothly open/close loads without slamming or too much effort.

- Choose matching fittings and ensure mounting brackets align.

- Select material and finish based on environment.

- Check support, warranty, and that Schutts Industrial offers the correct spares or replacements.

Why Choose Schutts Industrial?

- Long-standing reputation for quality and reliability.

- Wide range of heavy duty gas struts, end fittings, and accessories in stock.

- Transparent specifications — force ratings, sizes, finishes, and load details clearly provided.

- Support services like calculators and customer service for selection help.

Conclusion

Choosing the best heavy duty gas struts from Schutts Industrial requires attention to load, length, fitting, and material. By following the steps above you ensure safety, performance, and longevity. With its broad selection, transparent details, and supportive service, Schutts Industrial offers everything you need to pick the right gas struts for any job. Make your selection wisely—your equipment (and your peace of mind) depend on it.